Sales Hot-line: +86-189 0627 1888 Contact Person: Mr.Hu Fax: +86-513-8844 8088

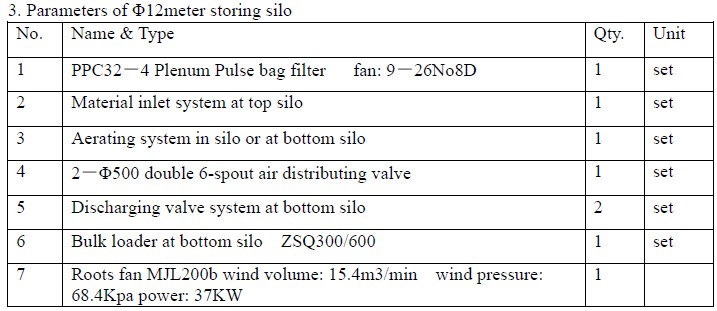

1. Brief introduction

Cement storing silo is designed with a mixing cone chamber in the central bottom of silo to reduce the discharge pressure from material and to avoid the funnel flow. There are 8-12 feeding holes in mixing chamber. There are 8-12 aerating zones in the annular area between the mixing chamber and the wall of silo. When discharging, these aerating zones will emit the gas to the opposite annular area by turns so that the cement can flow into the central mixing Room. During discharging process, a mixing effect of gravity formed from cutting horizontal material layer is produced with materials' falling down and a further homogenization in the mixing silo is done for materials with continuously aerating blending. Discharge material from side silo discharge units with the gravity of cutting horizontal material layer up and down. Even value range is 5-9 and electricity consumption is 0.15-0.30kwh/t.

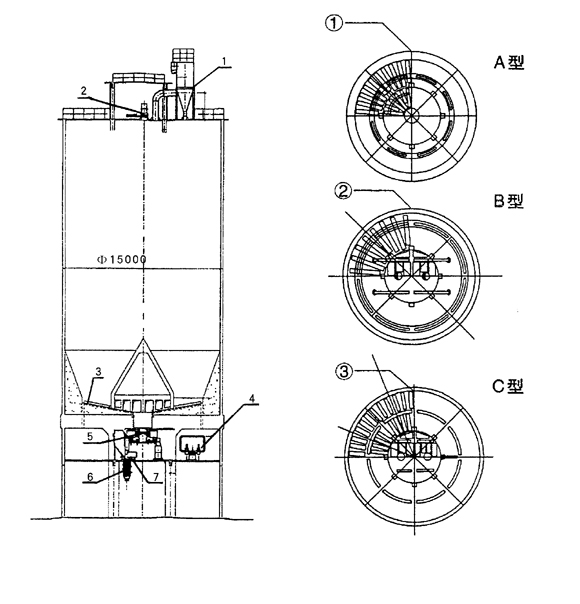

2. Drawing