Sales Hot-line: +86-189 0627 1888 Contact Person: Mr.Hu Fax: +86-513-8844 8088

I. Brief introduction

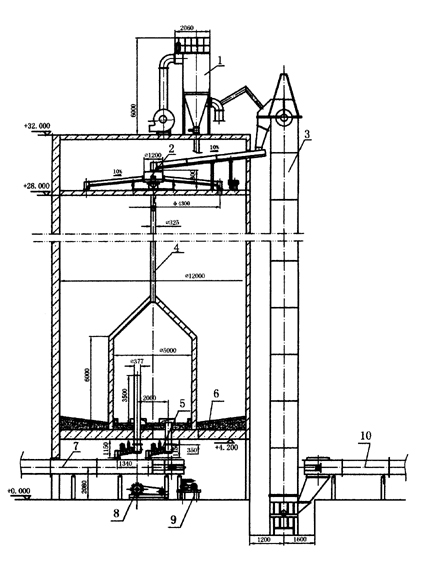

Continuous homogenizing silo is characterized as following: raw material is fed from top silo and discharged after aerating and mixing continuously. A column-shape mixing chamber is installed in the central bottom of the silo to reduce the discharge pressure of material in silo and to avoid the funnel flow. There are 6-12 discharging holes in mixing chamber and 6-12 aerating zones between the mixing chamber and the silo wall. When discharging, raw material entered into central room by turns. The material is mixed further in the mixing chamber by aerating continuously and qualified raw material is discharged from high level overflowing pipe. The surplus air is exhausted to the outer row and pumped to dust filtering device to purify. The raw material preparation system is required as it is featured with continuous, stable and reliable, little investment, low electric consumption, flexible process layout, compact structure, easy operation and so on. The range of its even value is 5-9 and electric consumption is 0.1-0.2kwh/t.

II. Drawing

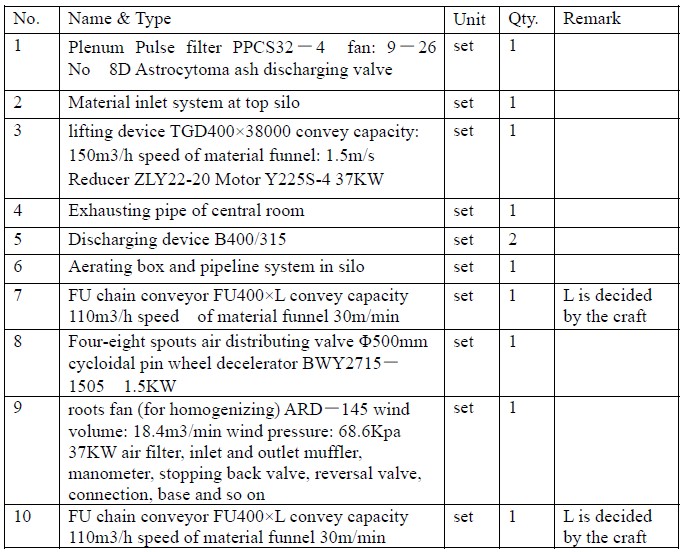

III. Equipments list of Φ12 meter continuous homogenizing silo